PT. Cefa Indonesia Sejahtera Lestari

Our Journey

Take a journey through the history of PT. Cefa Indonesia Sejahtera Lestari. We are like caretakers of a precious bird, fostering sustainable prosperity by exporting bird’s nest.

About Us

PT. Cefa Indonesia Sejahtera Lestari is a Bird’s Nest processing company located in North Sumatra, driven a heartfelt commitment for producing the Best Quality & Food Safety Product for exporting its product to Republic of China, Certified by GACC. We are supported by big Processing Bird’s Nest plant & by dedicated team of hundred employes.

Our Vision

We aspire to make PT. Cefa Indonesia Sejahtera Lestari as a nationally cherished private company with a global footprint, we maintain exceptional qual ity and ensuring top-tier food safety in every product we export.

Our Mission

We continually improve our Quality and Food Safety Management System, invest in nurturing our Human Resources, develop our Infrastructure, and harness the latest Technology. Our goal is to consistently deliver pristine, high-quality bird’s nests that not only meet customer satisfaction but also exceed regulatory requirements

Resources

PT. Cefa Indonesia Sejahtera Lestari, registered under Number 041, operates 19 Swiftlet Houses. Together, they boast an annual production capacity of 33,968 tons. These Swiftlet Houses are proudly registered with the Indonesian Agriculture Quarantine and strategically spread across the diverse landscapes of Indonesia.

Production

01. PREPARING

02. CLEANING

03. MOULDING

04. DRYING

05. QUALITY CONTROL

06. HEATING

07. WRAPPING

08. PACKING

09. WAREHOUSE

10. LABORATORY

11. TRACEABILITY

12. NEST TRANSFER FLOW

Product

Support Process

01. DINING ROOM

02. WATER TREATMENT

03. HYGIENE

04. LOCKER

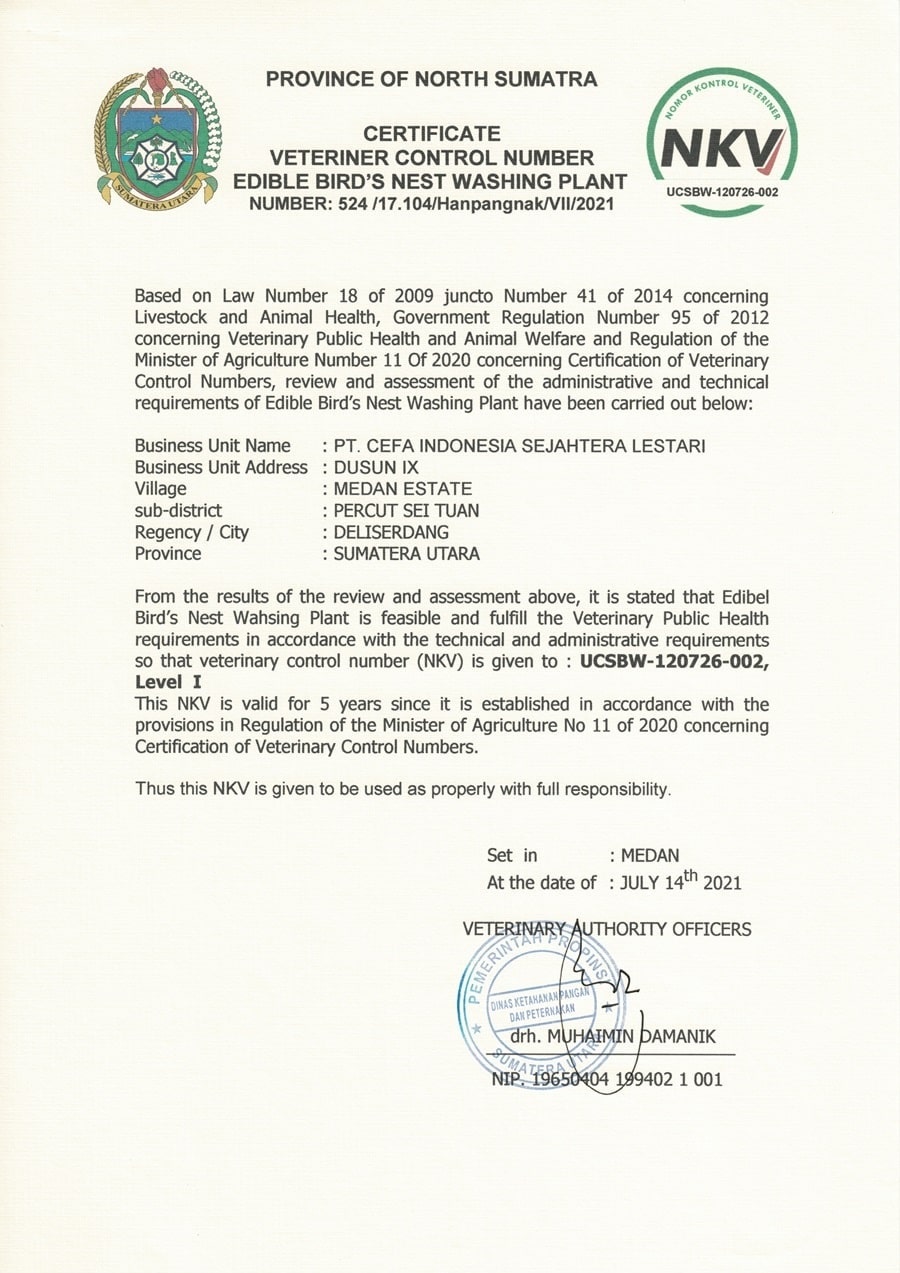

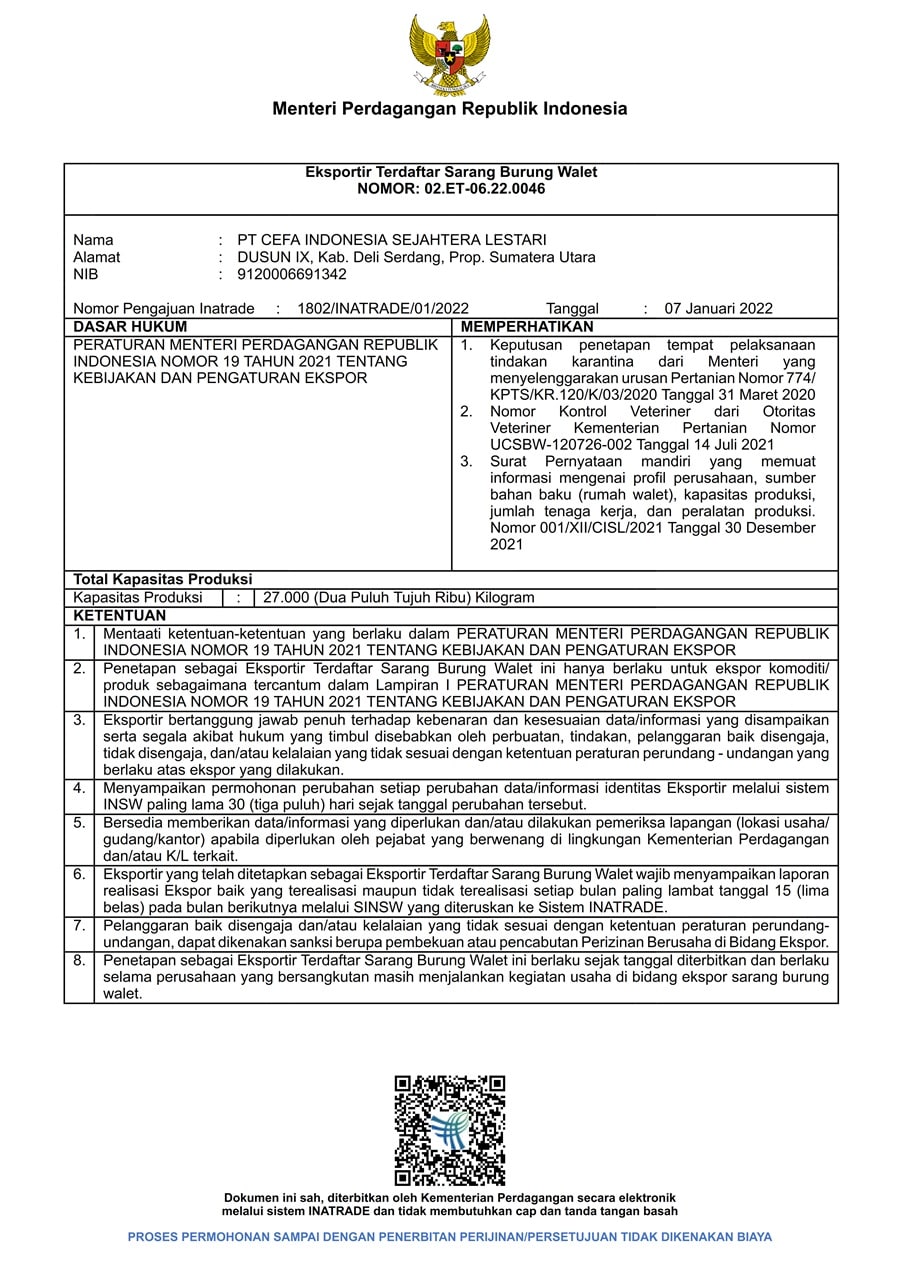

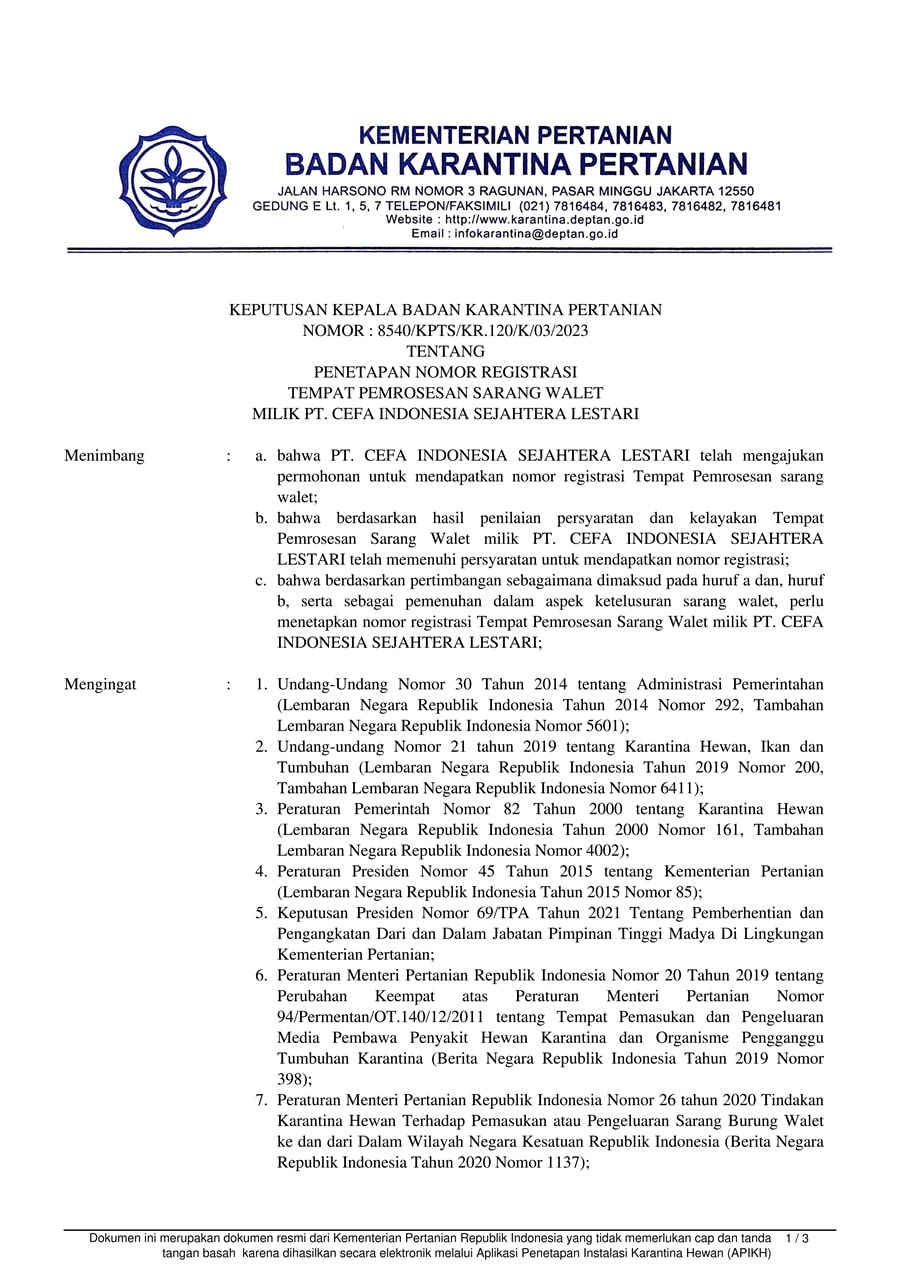

CERTIFICATION / ACCREDITATION

GACC Registered

Our Contact

- +62 8137-0158-226

- (Office) +62 61 7338-3239

- pt.cefaindonesia@yahoo.com

- Dusun IX, Kelurahan Medan Estate, Kecamatan Percut Sei Tuan, Kabupaten Deli Serdang, Sumatera Utara 20371 - Indonesia